Storage

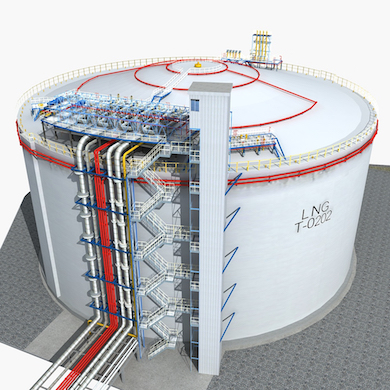

Tank Storage

Global Tankcontainer Services continually strive to provide market-leading solutions for all types of storage needs, in both caverns and tanks, operating 24 hours a day.

All our storage facilities are situated in strategic, carefully selected locations across the Nordic region, our flexibility and wide range of solutions enable us to store a selection of products and qualities.

Through ownership, joint ventures and long-term partnership agreements, we can always provide large storage capacity and innovative solutions at competitive prices. Our pursuit of the highest standards and security means we continually invest in new technology and effective infrastructure at our terminals.

Global Tankcontainer Services owns and operates fuel storage and facilities. More than 7.5 million barrels of bulk fuel are stored in our bulk storage tanks. For our ethanol and biofuel supply, our terminals include multi-modal capabilities (pipeline, truck, rail, and light oil barges), as well as art blending processes. Global Tankcontainer Services also has third-party agreements throughout the Netherlands that allow us to market from approximately 20 terminals. Use the interactive map below to locate a terminal that meets your company’s needs.

The tanks are linked to the pumps that serve the long-distance pipelines by subterranean transfer pipes that are centralized remotely operated and run between the tanker pier and the tanks itself. It is also feasible to move different grades of crude oil to different portions of the tank farm in order to achieve specific desired characteristics and qualities in the crude oil and feedstock, for example. Additionally, crude oil can be transported to and from the caves through the tanks.

Whichever process is currently in operation, any batch of crude oil entering Global Tankcontainer Services be it from a tanker or from a cavern — is first sent through the tanks in order to have its quantity measured before it is pumped into long-range pipelines. The most important function of the tank farm is that it acts as a buffer. Using this buffer, cargoes of crude oil from tankers arriving at irregular intervals can be dispatched in batches efficiently, and continuous operation of the long-range pipelines can simultaneously be ensured.

One of the company’s structural divisions is in charge of storage management, as well as third-party technical administration of storage facilities. One of the technical department’s pillars is to ensure that ships operate optimally in both technical and economic aspects, is a competent organization, and ensures tank maintenance and performs customer functions in the construction of storage tanks. The organization keeps a close eye on the storage facilities’ technical condition, as well as the functioning of all units and mechanisms, and ensures that they are serviced on time. Global Tankcontainer Services management expresses a strong commitment to the policy’s application. We look forward to the cooperation of all employees and others who work for us in order to gain our clients’ trust by providing exceptional performance and quality in our tank farms.